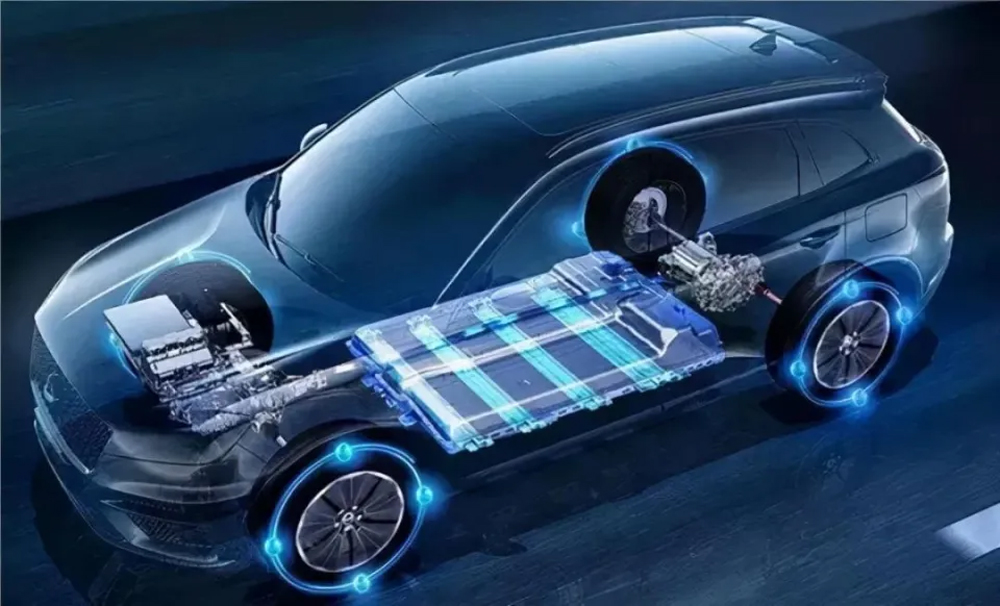

Battery Packs

As manufacturers strive to increase the range of new energy vehicles, vehicles need to design as many cells as possible in a given space, and many battery packs consisting of individual cells in a battery module will generate heat and accumulate in a relatively small space during vehicle operation. Due to the dense stacking of cells in the battery pack, it is also relatively difficult to dissipate heat in the middle area, exacerbating the temperature inconsistency between cells, which will reduce the charging and discharging efficiency of the battery and affect the battery's power; and in serious cases, it will also lead to thermal runaway, which will affect the system's safety and lifespan. Thermal management materials can quickly conduct the heat generated by charging and discharging to the heat dissipation elements, and the materials can protect the battery from liquids, harsh environments, vibrations and thermal shocks in an all-round way.

Polyurethane thermally conductive structural adhesive BN-PU6012, BN-PU6003 is applied in the thermal conductivity and structural bonding between the battery cell and water-cooling plate, and between the battery cell and shell, with high bonding strength, good toughness, and at the same time, good aging and chemical resistance, which can achieve the low-cost and rapid assembly of the battery.

Flame-retardant insulating sheet BN-FP is applied between the cells and the casing, which has excellent flame-retardant properties, anti-aging properties, excellent mechanical properties, and electrical insulation properties.

Thermally conductive spacer BN-FS series is used to fill the gap between the shell and PCB components and conduct heat. Thermally conductive spacer improves the thermal performance and reliability by removing air and reducing the thermal resistance of the interface.

Battery Pack Solutions