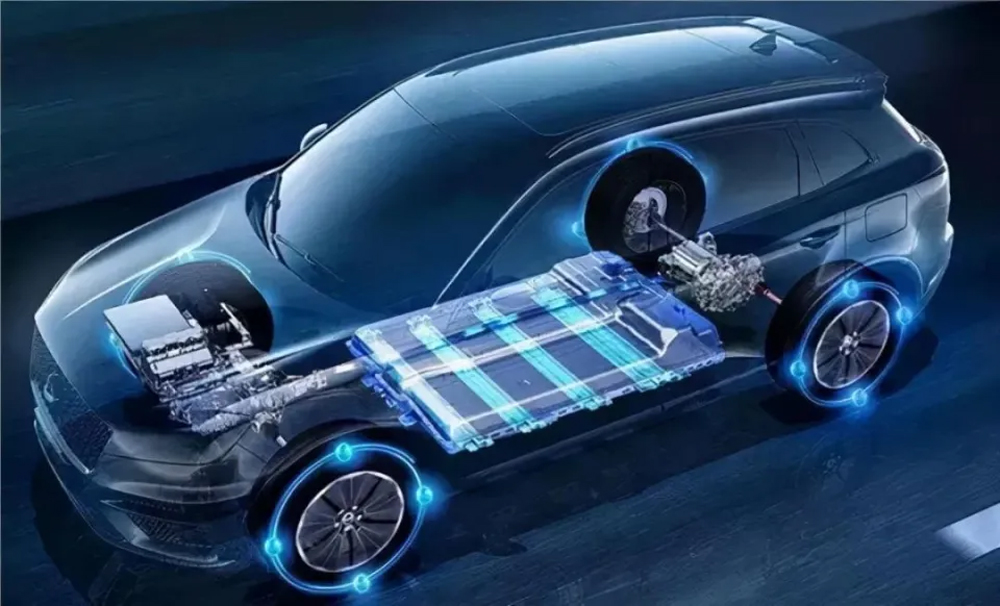

On-Board Power Control System

On-board charger OBC is a power battery power conversion device, but also an important part of the new energy electric vehicle power system. On-board charger due to high-power charging and discharging, the electronics, chips, MOSFETs, etc., which generate a lot of heat inside the casing, need to conduct the heat out in a timely manner, otherwise it will greatly reduce the life and performance of the internal components. This requires these electronic devices to be in contact with the inner wall of the metal casing in order to effectively achieve heat conduction and heat dissipation. Thermal interface materials (thermally conductive spacers, thermally conductive insulating films, thermally conductive gels, thermally conductive potting adhesives, etc.) not only provide excellent thermal conductivity, but also effectively fill the uneven gaps in the surface of the devices and heat sinks to exclude the air, and to establish an effective thermal conduction path.

The thermally conductive insulating film/heat curing thermally conductive adhesive film BN-TK15 of the BNG series based on glass fibre and the BNK series based on polyimide film is used between power tubes and heat sinks, and this thermally conductive material achieves the functions of insulating resistance to voltage and resistance to tearing.

Thermally Conductive Potting Adhesive BN-RT120, BN-RT150 can effectively fix small electronic components (inductors, etc.) to prevent damage caused by bumping, fill the gap between irregular heat sources (transformers, capacitors, etc.) and heat sinks, so that the inductor heat can be well conducted out, to protect the stability of the internal structure, has a low viscosity, accelerated curing at room or high temperatures, high thermal conductivity, high temperature and flame retardant properties. Characteristics.

Thermally conductive sealant BN-RT200H series is used for sealing of shell and adhesive fixing of internal components.

Thermally conductive gels BN-RT320, BN-RT420 not only have good thermal conductivity, but also insulation and operability, which can achieve large-scale automated production. High thixotropy, effective filling of uneven gaps, and vibration damping can ensure that the system operates under a stable structure, and at the same time can conduct heat out in time.

Thermally conductive spacer BN-FS150SP, BN-FS300SP are mainly used in the case of large interface gaps; stress absorption in the case of relatively large tolerances; assemblies with frequent vibration in the application process; suitable for thermally conductive material assemblies and whole machine assemblies in different places.

Flame retardant insulating sheets BN-FP series are applied at the outer shell and inner wall, with excellent flame retardant properties, anti-aging properties, mechanical properties, electrical insulation properties and so on.